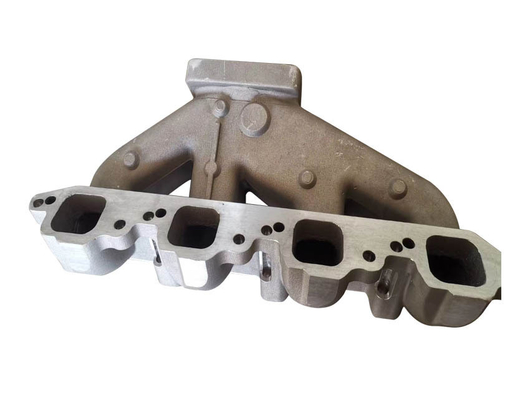

Mechanical Engineering Gravity Casting Parts , Industrial Spare Parts Anti Corrosion

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | OEM/ODM |

| Minimum Order Quantity | 100pcs |

| Price | Confirm price based on product |

| Packaging Details | Bubble Bags, Corrugated Carton,Pallet or as per customer`s requirement on Casting Parts |

| Delivery Time | Tooling: 4~12 weeks update part size; Samples: one week if no finish and CNC machining required; Production:2~3weeks |

| Payment Terms | Advance 30% deposit and ship after receiving 70% final payment |

| Supply Ability | 500 tons of aluminum alloy material |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Copper Alloy | Payment Term | T/T, L/C, PayPal, Western Union |

|---|---|---|---|

| Quality Control | Professional Inspection | Surface Treatment | Polishing, Anodizing, Plating, Painting, Powder Coating |

| Drawing Format | PDF, CAD, IGS, STP, X_T | Shipping | By Sea, By Air, By Express |

| Packaging | Carton, Wooden Case, Pallet | Casting Method | Gravity Casting |

| High Light | Mechanical Gravity Casting Parts,Engineering Gravity Casting Parts,Industrial Spare Parts Anti Corrosion |

||

Professional Inspection Gravity Casting Parts 0.1-100kg OEM Service

Product Description:

Gravity casting parts refer to a casting process in which the molten metal is poured into a mold that is held in a gravity field. The gravity casting parts produced by this process are usually of high quality, with casting weights ranging from 0.1 to 100kg. Our gravity casting services are designed to provide our customers with a variety of casting elements, components, and assemblies that meet their exact specifications. Advanced inspection equipment including CMM, projector, hardness tester, and salt spray tester are used to ensure that the parts are precisely machined to meet the tolerance requirement of ±0.01mm. Our OEM service is also available, and we are committed to meeting our customers’ needs.

We specialize in providing gravity cast parts, gravity casting assemblies, gravity casting elements, and gravity casting components that are of superior quality and long-lasting performance. Our experienced engineers and technicians are always ready to assist our customers with the selection of the most appropriate gravity casting process to meet their specific requirements.

Features:

- Product Name: Gravity Casting Parts

- Surface Treatment: Polishing, Anodizing, Plating, Painting, Powder Coating

- Processing Equipment: CNC Machining Center, Lathe, Milling Machine, Drilling Machine

- Payment Term: T/T, L/C, PayPal, Western Union

- Inspection Equipment: CMM, Projector, Hardness Tester, Salt Spray Tester

- Material: Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Copper Alloy

- Gravity Casting Assemblies, Gravity Cast Assemblies, Gravity Cast Assemblies

Technical Parameters:

| Product Attributes | Details |

|---|---|

| Material | Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Copper Alloy |

| Casting Method | Gravity Casting |

| Packaging | Carton, Wooden Case, Pallet |

| Tolerance | ±0.01mm |

| Lead Time | 15-30 Days |

| Payment Term | T/T, L/C, PayPal, Western Union |

| Quality Control | Professional Inspection |

| Inspection Equipment | CMM, Projector, Hardness Tester, Salt Spray Tester |

| Drawing Format | PDF, CAD, IGS, STP, X_T |

| Casting Size | Customized |

| Gravity Cast Assemblies | Gravity Cast Components, Gravity Casted Parts |

Applications:

Gravity Casting Parts are widely used in a variety of industries such as agricultural machinery, engineering machinery, auto parts, construction machinery, valves and pumps, aerospace, medical instruments, and many more. With their high strength and precision, Gravity Casting Parts are ideal for producing components with complex shapes and tight tolerances. Because of their low cost and fast production time, these parts are an economical and reliable choice for custom-made parts. OEM/ODM brand name, Guangdong, China is the place of origin and the minimum order quantity is 100pcs. The price is confirmed based on the product. Packaging details include bubble bags, corrugated carton, pallet or as per customer’s requirement. The delivery time includes tooling: 4-12 weeks, samples: one week if not finish and CNC machining required, and production: 2-3 weeks. Payment terms are advance 30% deposit and ship after receiving 70% final payment. The supply ability is 500 tons of aluminum alloy material and OEM service is provided. The casting weight is from 0.1-100kg, casting size can be customized, and the lead time is 15-30 days. Material used can be Aluminum Alloy, Zinc Alloy, Magnesium Alloy, or Copper Alloy. Gravity Casting Parts, Gravity Casting Components, and Gravity Casted Components are all available.

Customization:

We offer custom-made Gravity Casted Parts and Gravity Casted Components with OEM/ODM service. Our Gravity Casted Parts and Gravity Casted Components are made in Guangdong,China with the Minimum Order Quantity of 100pcs. The price for our products is to be confirmed based on product. We provide Carton, Wooden Case, Pallet and other packages as per customer`s requirement. The Tooling time for our products is 4~12 weeks depending on part size. For Samples, it will take one week if no finish and CNC machining is required. The Production time is 2~3weeks. We accept Advance 30% deposit and ship after receiving 70% final payment. We have a Supply Ability of 500 tons of aluminum alloy material. We can provide shipping service by Sea, Air or Express. The Dimensions and Casting Size are Customized according to drawing requirements or sample.

Support and Services:

Gravity casting is a metal casting process where molten metal is poured into a mold cavity under the force of gravity. Our gravity casting parts are designed and manufactured with precision and accuracy for superior performance.

Our dedicated technical support team is here to help ensure that your parts are designed and manufactured properly to meet your specific requirements. We are committed to providing you with knowledgeable and timely support.

Our team of experienced engineers and technicians is available to assist you with any questions or concerns you may have about the design and manufacture of gravity casting parts. We can also provide technical advice on the best casting process for your specific application.

We also offer a range of additional services, including on-site support, training and consultation. Our team can also assist with troubleshooting, defect analysis and product testing.

If you have any questions or require technical support for your gravity casting parts, please do not hesitate to contact us.

Packing and Shipping:

Packaging and Shipping for Gravity Casting Parts:

Gravity casting parts will be securely packaged and shipped in specialized containers designed to protect the product. The packaging materials used must meet all applicable local, state, and national regulations. The parts should be inspected for any external damage prior to shipping. Any damaged parts should be reported and replaced before shipping.

Packaging will depend on the size and weight of the parts, as well as the customer’s requirements. Generally, parts will be packaged in foam-lined boxes or trays and then placed in larger shipping containers. The shipping containers should be marked with the customer's name, address, and any other pertinent information.

Shipping will be done via ground, air, or sea, depending on the customer's requirements. All shipping must meet the customer's delivery expectations. The customer should be notified of shipment and tracking information.

FAQ:

A1: OEM/ODM

A2: Guangdong, China

A3: The minimum order quantity is 100pcs.

A4: The price of the Gravity Casting Parts depends on the product. Please contact us for more detailed information.

A5: The delivery time is 4-12 weeks for tooling, 1 week for samples if no finish and CNC machining required, and 2-3 weeks for production.