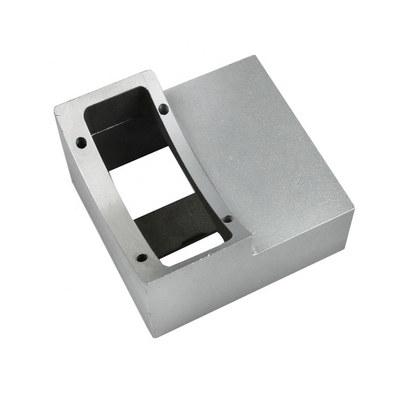

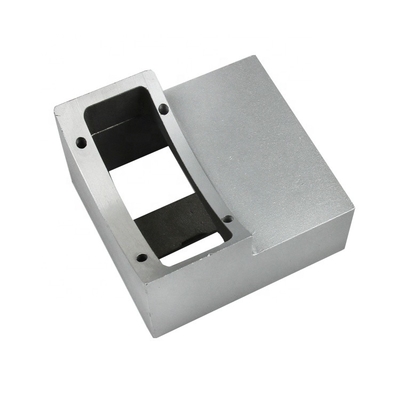

Powder Coated Gravity Die Casting Components With Zinc Alloy Copper Alloy Material

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | OEM/ODM |

| Minimum Order Quantity | 100pcs |

| Price | Confirm price based on product |

| Packaging Details | Bubble Bags, Corrugated Carton,Pallet or as per customer`s requirement on Casting Parts |

| Delivery Time | Tooling: 4~12 weeks update part size; Samples: one week if no finish and CNC machining required; Production:2~3weeks |

| Payment Terms | Advance 30% deposit and ship after receiving 70% final payment |

| Supply Ability | 500 tons of aluminum alloy material |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Inspection Equipment | CMM, Projector, Hardness Tester, Salt Spray Tester | Service | OEM Serivice |

|---|---|---|---|

| Lead Time | 15-30 Days | Casting Weight | 0.1-100kg |

| Drawing Format | PDF, CAD, IGS, STP, X_T | Casting Size | Customized |

| Payment Term | T/T, L/C, PayPal, Western Union | Tolerance | ±0.01mm |

| High Light | Powder Coated Gravity Die Casting Components,Zinc Alloy Gravity Die Casting Components,Copper Alloy Gravity Die Casting Components |

||

Powder Coated Customized Gravity Cast Components With PayPal Payment

Product Description:

Gravity Casting Parts are precision casted components made with the gravity casting process. Our gravity casting process ensures superior quality and accuracy, with accurate replication of intricate shapes and components. We use the latest CNC Machining Centers, Lathes, Milling Machines and Drilling Machines to ensure efficient production and quality control. Our Gravity Casting Parts come in a variety of intricate shapes and sizes and can be customized according to customer specifications. All of our Gravity Casted Components and Gravity Casting Components are professionally inspected to ensure the highest quality product. We accept a variety of drawing formats including PDF, CAD, IGS, STP and X_T. Our Lead Time is usually within 15-30 Days and our Payment Terms can be T/T, L/C, PayPal or Western Union.

Features:

- Product Name: Gravity Casting Parts

- Shipping: By Sea, By Air, By Express

- Inspection Equipment: CMM, Projector, Hardness Tester, Salt Spray Tester

- Tolerance: ±0.01mm

- Casting Size: Customized

- Lead Time: 15-30 Days

- Gravity Casted Components, Gravity Casting Elements, Gravity Casted Components

Technical Parameters:

| Parameter | Description |

|---|---|

| Tolerance | ±0.01mm |

| Processing Equipment | CNC Machining Center, Lathe, Milling Machine, Drilling Machine |

| Quality Control | Professional Inspection |

| Casting Method | Gravity Casting |

| Lead Time | 15-30 Days |

| Inspection Equipment | CMM, Projector, Hardness Tester, Salt Spray Tester |

| Shipping | By Sea, By Air, By Express |

| Dimensions | Drawing Requirements Or Sample |

| Material | Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Copper Alloy |

| Surface Treatment | Polishing, Anodizing, Plating, Painting, Powder Coating |

| Product Name | Gravity Casting Parts, Gravity Casting Components, Gravity Casting Elements |

Applications:

Gravity Casting Parts offer a wide range of application scenarios and venues for customers. With OEM/ODM brand name, Guangdong, China as the place of origin, the minimum order quantity of 100pcs, the price will be confirmed based on product requirements, bubble bags, corrugated carton, pallet or customers' requirements can be selected for packaging, tooling will take 4-12 weeks, samples can be obtained in one week if no finish and CNC machining is required and production will take 2-3 weeks, payment terms require a 30% advance deposit and the balance after shipment, with a supply capacity of 500 tons of aluminum alloy material, packaging with cartons, wooden cases, pallets, aluminum alloy, zinc alloy, magnesium alloy, copper alloy as materials, shipping options include by sea, by air, by express, drawing formats include PDF, CAD, IGS, STP, X_T, and with professional inspection for quality control, Gravity Casting Parts are suitable for a wide range of applications. They can be used for various purposes such as casting automotive parts, manufacturing communication parts, producing medical device parts, producing industrial machine parts and various other industries. Gravity Casting Parts are also popular for its durability, accuracy, and cost-effectiveness.

Customization:

- Brand Name: OEM/ODM

- Place of Origin: Guangdong,China

- Minimum Order Quantity: 100pcs

- Price: Confirm price based on product

- Packaging Details: Bubble Bags, Corrugated Carton,Pallet or as per customer's requirement on Casting Parts

- Delivery Time: Tooling: 4~12 weeks update part size; Samples: one week if no finish and CNC machining required; Production:2~3weeks

- Payment Terms: Advance 30% deposit and ship after receiving 70% final payment

- Supply Ability: 500 tons of aluminum alloy material

- Dimensions: Drawing Requirements Or Sample

- Material: Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Copper Alloy

- Shipping: By Sea, By Air, By Express

- Casting Method: Gravity Casting

- Tolerance: ±0.01mm

- Special Features: Gravity Casting Elements, Gravity Cast Components, Gravity Casting Components

Support and Services:

Gravity Casting Parts offers technical support and services to ensure that your product is functioning as efficiently and effectively as possible. Our team of experienced engineers is available to provide assistance with any issues you may encounter during installation, operation, or maintenance of your product.

We provide a variety of services, including:

- Troubleshooting

- Installation guidance

- Maintenance advice

- Software updates

- Product customization

- Replacement parts

If you need any help, please don't hesitate to contact us. We are here to help you get the best performance from your product.

Packing and Shipping:

Gravity casting parts are usually packaged and shipped in the following ways:

- Bubble wrap and cardboard boxes, in order to protect the parts from damage during shipping.

- Pallets and crates, for larger orders, to ensure the parts are securely packed and delivered safely.

- Customized packaging, for special requirements, such as additional protection or special labeling.

The shipping methods for gravity casting parts depend on the size and weight of the order, as well as the destination. Common shipping methods include air and sea freight, as well as trucking.

FAQ:

Q1: What is Gravity Casting Parts?A1: Gravity Casting Parts is a process of pouring molten metal into a mold in a gravity form. It is the most common process for producing aluminum alloy parts. Q2: What are the brand name and place of origin for Gravity Casting Parts?

A2: Brand Name of Gravity Casting Parts is OEM/ODM, and it is produced in Guangdong, China. Q3: What is the minimum order quantity for Gravity Casting Parts?

A3: The minimum order quantity for Gravity Casting Parts is 100 pieces. Q4: What is the price of Gravity Casting Parts?

A4: The price of Gravity Casting Parts is based on the product and needs to be confirmed. Q5: What is the packaging and delivery time for Gravity Casting Parts?

A5: The packaging for Gravity Casting Parts is Bubble Bags, Corrugated Carton, Pallet or as per customer's requirement. The delivery time is 4-12 weeks for tooling, 1 week for samples and 2-3 weeks for production.