Magnesium Alloy Gravity Die Casting Components For Mechanical Parts

| Place of Origin | Guangdong,China |

|---|---|

| Brand Name | OEM/ODM |

| Minimum Order Quantity | 100pcs |

| Price | Confirm price based on product |

| Packaging Details | Bubble Bags, Corrugated Carton,Pallet or as per customer`s requirement on Casting Parts |

| Delivery Time | Tooling: 4~12 weeks update part size; Samples: one week if no finish and CNC machining required; Production:2~3weeks |

| Payment Terms | Advance 30% deposit and ship after receiving 70% final payment |

| Supply Ability | 500 tons of aluminum alloy material |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Dimensions | Drawing Requirements Or Sample | Shipping | By Sea, By Air, By Express |

|---|---|---|---|

| Casting Size | Customized | Material | Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Copper Alloy |

| Lead Time | 15-30 Days | Casting Weight | 0.1-100kg |

| Surface Treatment | Polishing, Anodizing, Plating, Painting, Powder Coating | Tolerance | ±0.01mm |

| High Light | Magnesium Alloy Gravity Die Casting Components,Mechanical Gravity Die Casting Components |

||

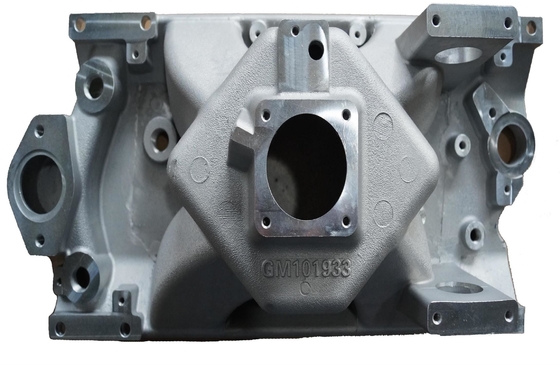

Magnesium Alloy Gravity Casted Parts Shipping By Sea

Product Description:

Gravity casting parts is a specialized production process for manufacturing custom-sized assemblies and components of high precision with excellent surface finish. Our advanced gravity casting process utilizes a form of permanent mold casting, where molten metal is cast into a mold, then removed and cooled. We use both manual and automated processes to produce parts with high accuracy and repeatability. Our gravity casting equipment is capable of producing parts of various sizes and shapes with a superior surface finish. We provide a variety of surface treatments such as polishing, anodizing, plating, painting, and powder coating. Our experienced engineers and technicians have extensive knowledge of gravity cast assemblies, parts and components. With our advanced processing equipment, including CNC machining centers, lathes, milling machines, and drilling machines, we can produce precision parts with tolerance of ±0.01mm and lead time of 15-30 days.

Features:

- Gravity Casting Parts: Polishing, Anodizing, Plating, Painting, Powder Coating

- Casting Weight: 0.1-100kg

- Dimensions: Drawing Requirements Or Sample

- Quality Control: Professional Inspection

- Drawing Format: PDF, CAD, IGS, STP, X_T

- Gravity Casting Components: High-precision and Dimensionally Accurate

- Gravity Casting Assemblies: Complex Shapes and Designs

Technical Parameters:

| Property | Value |

|---|---|

| Casting Method | Gravity Casting |

| Packaging | Carton, Wooden Case, Pallet |

| Tolerance | ±0.01mm |

| Drawing Format | PDF, CAD, IGS, STP, X_T |

| Inspection Equipment | CMM, Projector, Hardness Tester, Salt Spray Tester |

| Processing Equipment | CNC Machining Center, Lathe, Milling Machine, Drilling Machine |

| Casting Size | Customized |

| Casting Weight | 0.1-100kg |

| Dimensions | Drawing Requirements Or Sample |

| Material | Aluminum Alloy, Zinc Alloy, Magnesium Alloy, Copper Alloy |

Applications:

Gravity Casting Assemblies, Gravity Casting Components and Gravity Casting Parts are brand-name OEM/ODM products made in Guangdong, China. With a minimum order quantity of 100pcs, the price and packaging details of Casting Parts can be confirmed based on the product. It takes 4~12 weeks to complete tooling, one week to finish samples if no further machining is required, and 2~3weeks for production. Advance 30% deposit and ship after receiving 70% final payment. 500 tons of aluminum alloy material is available for supply. Quality control is ensured with CMM, Projector, Hardness Tester and Salt Spray Tester. Casting weight ranges from 0.1 to 100kg with tolerance of ±0.01mm. Payment terms include T/T, L/C, PayPal, Western Union, and materials options such as aluminum alloy, zinc alloy, magnesium alloy and copper alloy.

Customization:

Gravity Casting Parts provide OEM/ODM brand name with customized services. The place of origin is Guangdong, China and the minimum order quantity is 100pcs. The price is confirmed based on product. Packaging details include bubble bags, corrugated carton, pallet or customer’s requirement on casting parts. Delivery time includes tooling: 4~12 weeks for updating part size; Samples: one week if no finish and CNC machining required; Production: 2~3 weeks. Payment terms are advance 30% deposit and ship after receiving 70% final payment. The supply ability is 500 tons of aluminum alloy material. Surface treatment includes polishing, anodizing, plating, painting, powder coating. Casting size is customized. Material includes aluminum alloy, zinc alloy, magnesium alloy, copper alloy. Inspection equipment includes CMM, projector, hardness tester, salt spray tester. Quality control is professional inspection. We focus on gravity casting elements, gravity casted components, gravity casting assemblies.

Support and Services:

We offer technical support and services for Gravity Casting Parts. Our experts are available to help ensure your parts are cast to the highest quality and meet all your requirements. We offer a variety of services, including casting design, material selection, process optimization, simulation and mold design. We also provide on-site technical support and guidance to ensure your parts are cast correctly and efficiently. We ensure that our parts meet the highest quality standards and are delivered on time.

Packing and Shipping:

Gravity casting parts are typically packaged in protective materials such as bubble wrap, cardboard, foam, and other materials in order to protect them from damage during shipping. The parts may also be sealed in a plastic bag to help keep out moisture. The package may also include a packing slip, which will include the customer's order number, a list of the items included in the package, and the customer's address.

The parts will typically be shipped via a trusted carrier such as UPS, FedEx, or DHL. The parts may also be shipped via an expedited service such as next-day delivery in order to ensure that the customer receives them in a timely manner.